Overview

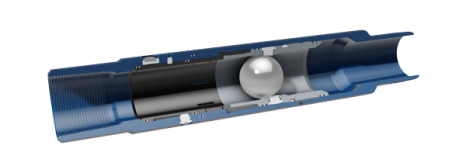

Tartan Completion’s MultiFrac™ limited-entry, ball-drop system combines patented MultiFrac hydro-mechanical sleeves with patent-pending BurstPoint™ ports to improve stimulation treatment placement and effectiveness. The MultiFrac system simultaneously stimulates multiple stages (cluster) with a single fracture treatment at surface.

By enabling increased stage count without increasing the quantity of activation balls, this system is designed to provide a higher density of stages to evenly distribute stimulation treatments throughout the entire wellbore. The MultiFrac system provides complete control of the stimulation while offering a more complex fracture network.

Application

- Single design for open hole or cemented liner installations

- Cluster (batch) stimulation of multiple stages at the same time

- Ability to stimulate 150+ stages

Features and benefits

- Faster completion times due to limited-entry stimulation of multiple stages with a single treatment from surface

- One ball activates multiple MultiFrac sleeves, allowing for higher stage density within the same length of wellbore

- MultiFrac sleeves have no communication with the annulus until BurstPoint port rupture pressure is reached

- BurstPoint port inserts prevent erosion, allowing cluster efficiency of ≥90% throughout the treatment stage

- BurstPoint ports can be sized to control the fracture fluid rate on a per sleeve basis

- Adjustable stimulation volumes enabling true limited-entry operations

- Positive surface indicators of multiple entry points, providing real-time parameters

- Enhanced fracture network results in increased wellbore conductivity

- Surface pressure indications are an accurate monitor of tool performance

- Rugged design for enhanced reliability

- Can be rotated to bottom

- Designed to handle the high torque capabilities of all premium and semi-premium connections

- Ball seats are designed for quick mill-out times

Fill out your information to receive the MultiFrac™ System data sheet.

Case Studies

MULTIFRAC™ D-J BASIN

Tartan MultiFrac systems successfully stimulated 18 months post-install.

MULTIFRAC BALL DROP SYSYTEM

Tartan Cemented MultiFrac Limited Entry Ball-Drop System Reduces Stimulation Time by 5 Days per Well Compared to Plug-and-Perf in the D-J Basin.

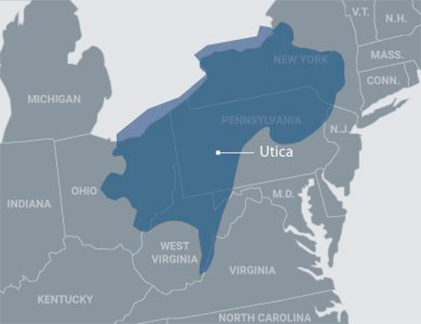

MULTIFRAC™ UTICA

Tartan cemented MultiFrac limited entry ball-drop systems increase production by 12.5%.