Completions Systems Overview

We designed our portfolio of patented completion innovations in response to our customers’ needs resulting in simple, reliable and flexible solutions that improve stimulation efficiencies and effectiveness, ultimately lowering operator costs per barrel.

Working with our customers, Tartan ensures the completion design for each well is tailored to deliver the specific stimulation program. Our in-house engineering and manufacturing allows for complete customization of tool characteristics, including threads, BurstPoint™ port sizes and burst pressures.

This complete supply channel and our commitment to outstanding field service ensures that our completion systems and tools meet our customers’ highest expectations – from design to installation through to well performance.

Whether it’s our repeatable and proven cemented sleeve completion designs or our high-performance open hole completion systems, we offer superior solutions for today’s extended reach horizontal wells.

CEMENTED SLEEVE Completion Systems: Repeatable, Reliable, Flexible

- Tartan Completions specializes in cemented sleeve completions to increase efficiency and make better wells. Our leading cemented sleeve completion systems and tools include:

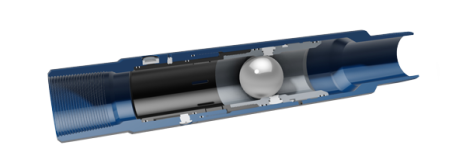

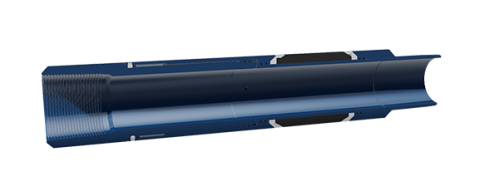

- MultiFrac™ limited-entry, ball-drop system

- EnerFrac™ single-entry, ball-drop system

- Initiation Assembly stimulates the deepest stages of hybrid cemented wellbores

- Cemented Initiation Sub initiates flow and can be used to stimulate the first stage at the toe

- Ball-Drop Cemented Initiation Sub tests liner pressure integrity prior to stimulation

OPEN HOLE Completion Systems: Simple, Reliable, Flexible

Tartan’s MultiFrac™ limited-entry and EnerFrac™ single-entry systems can also be run as open hole completions.

Tartan’s Isolation Packer provides single or multiple high-pressure zonal isolation

Tartan’s Hydraulic Initiation Port activates flow for the first stage of all MultiFrac limited-entry and EnerFrac single-entry systems

Toe Circulation Sub controls flow between the completion string and annulus